Over the last few years, subject material scientists and electronics engineers were seeking to fabricate new versatile inorganic fabrics to create stretchable and extremely appearing digital units. Those units can also be in response to other designs, akin to rigid-island energetic cells with serpentine-shape/fractal interconnections, impartial mechanical planes or bunked buildings.

In spite of the numerous developments within the fabrication of stretchable fabrics, some demanding situations have proved tough to conquer. For example, fabrics with wavy or serpentine interconnect designs regularly have a restricted space density and fabricating proposed stretchable fabrics is continuously each tough and costly. As well as, the stiffness of many current stretchable fabrics does now not fit that of human pores and skin tissue, making them uncomfortable at the pores and skin and thus now not very best for developing wearable applied sciences.

Researchers at Sungkyunkwan College (SKKU), Institute for Fundamental Science (IBS), Seoul Nationwide College (SNU), and Korea Complicated Institute of Science and Era (KAIST) have just lately fabricated a vacuum-deposited elastic polymer for creating stretchable electronics. This subject material, offered in Nature Electronics, may well be used to create stretchy field-effect transistors (FETs), which might be number one parts of maximum digital units available on the market nowadays.

“Not too long ago, quite a lot of approaches for adopting comfortable fabrics were proposed for creating intrinsically stretchable electronics which doesn’t want any explicit structural designs owing to their intrinsic deformability,” Donghee Son, some of the researchers who performed the find out about, informed Tech Xplore. “On the other hand, such units hired solution-processed dielectric fabrics and thereby come across essential demanding situations in attaining excessive electric performances.”

Answer-processed natural gate dielectric fabrics, fabrics that may transmit electrical energy with out engaging in it (i.e., insulating it), don’t seem to be specifically appropriate for the introduction of versatile electronics. Maximum particularly, they have got thicknesses within the micrometer-scale, deficient insulating performances, chemical instability and a low uniformity. As well as, they’re in most cases incompatible with standard microfabrication processes, making them tough to provide on a big scale.

Because of those obstacles, digital parts in response to those solution-processed fabrics are plagued through deficient gate controllability and excessive operation voltages, in addition to a restricted scalability. Son and his colleagues, in conjunction with different analysis groups international, have thus been seeking to create ultrathin, stretchable, scalable, and extremely appearing dielectrics with selection fabrication methods.

“In our find out about, we provide a brand new technique to the design of dielectric fabrics to unravel the aforementioned demanding situations in intrinsically stretchable digital units,” Son defined. “Our large-scale vacuum-deposited stretchable dielectric allows the scalable fabrication of intrinsically stretchable units with electric performances related to these fabricated the use of the non-stretchable inorganic and stretchable natural dielectric fabrics (e.g., Al2O3 deposited by way of atomic layer deposition & spin-coated viscoelastic layer).”

To create their polymer-based dielectric, Son and his colleagues first copolymerized two other monomers, particularly isononyl acrylate (INA) and 1,3,5-trimethyl-1,3,5-tryvinyl cyclotrisiloxane (V3D3) the use of a procedure referred to as initiated chemical vapor deposition (iCVD). The monomer INA acts as a comfortable phase, expanding the fabric’s stretchability, whilst V3D3 serves as a cross-linkable arduous phase, giving the polymer movie tough insulating homes.

“The blending ratio of the monomers (INA and V3D3) used to be optimized to succeed in each insulating and stretching functionality of the tool,” Son mentioned. “Our vacuum-deposited polymer dielectric with dielectric consistent of three.59 and breakdown area of two.3 MV/cm confirmed the identical oxide thickness (EOT) worth of lower than 200 nm, which is the bottom worth a number of the stretchable dielectric layers reported so far.”

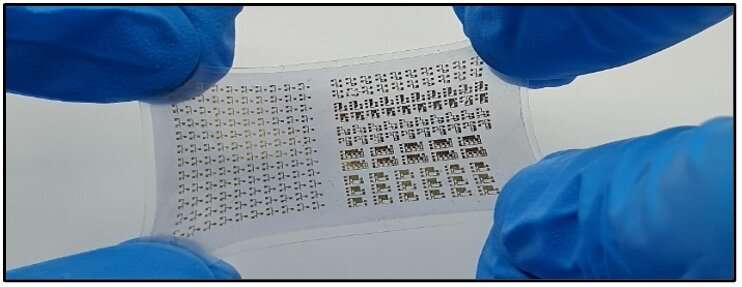

To show the promise in their subject material, the researchers used it to create transistors, after which used those to create stretchy inverters and common sense gates. In preliminary checks, those parts accomplished very promising effects.

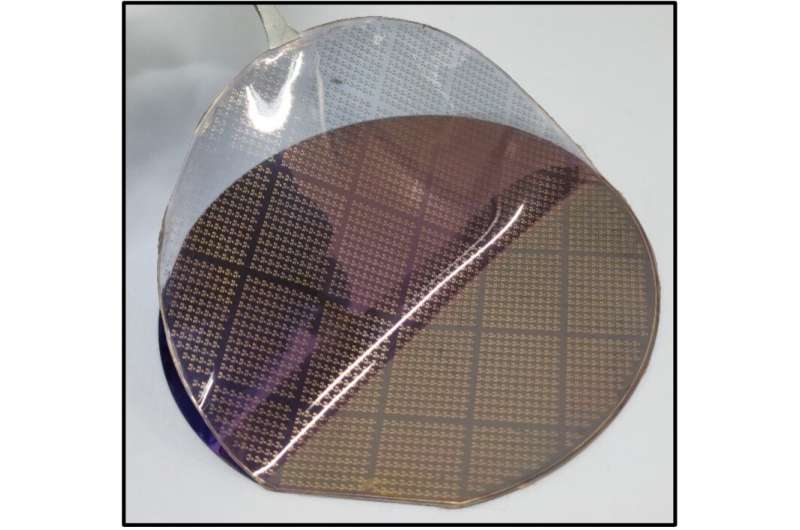

Along with a excessive dielectric consistent and a low EOT worth, they may well be stretched as much as a 40% pressure, whilst holding their insulating functionality. The crew additionally discovered that their subject material reveals a excessive chemical and thermal balance all over microfabrication processes and stays extremely uniform over vast spaces.

“Ours is the primary account of a vacuum-deposited stretchable dielectric, additionally demonstrating its utility to intrinsically stretchable digital units,” Son mentioned. “In different phrases, evaluating standard thick polymer dielectrics, a stretchable vacuum-deposited nanometer-thick movie (roughly 160 nm) has remarkable electric, mechanical, and chemical homes. The phenomenal benefits which can be inherent in our vacuum-deposited technique may just facilitate the improvement of high-performance wafer-scalable wearable units. The observations of our find out about would become the traditional paradigm of soppy electronics.”

At some point, the crew’s subject material may just permit the fabrication of latest intrinsically stretchable and extremely appearing transistors and common sense circuits that eat much less electric energy. Those transistors and circuits may well be used to create a large number of comfortable electronics, together with wearable and implantable units.

“I feel reaching an energy-efficient functionality in stretchable digital units will likely be a very powerful factor within the long-term building of dependable wearables,” Son added. “Thus, thickness of the vacuum-deposited insulating fabrics will have to be increasingly more thinner, to support gate controllability whilst keeping up stretchability. Moreover, its dielectric consistent could be progressed as much as over 10, which is analogous to that of the high-k inorganic dielectric.”

Additional info:

Ja Hoon Koo et al, A vacuum-deposited polymer dielectric for wafer-scale stretchable electronics, Nature Electronics (2023). DOI: 10.1038/s41928-023-00918-y.

© 2023 Science X Community

Quotation:

A brand new elastic polymer dielectric to create wafer-scale stretchable electronics (2023, February 17)

retrieved 1 March 2023

from https://techxplore.com/information/2023-02-elastic-polymer-dielectric-wafer-scale-stretchable.html

This record is matter to copyright. Except any truthful dealing for the aim of personal find out about or analysis, no

section could also be reproduced with out the written permission. The content material is equipped for info functions simplest.

Supply By means of https://techxplore.com/information/2023-02-elastic-polymer-dielectric-wafer-scale-stretchable.html