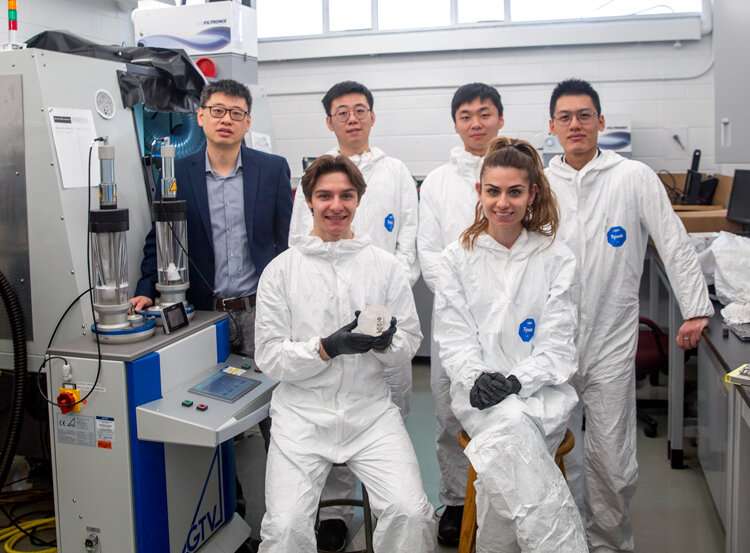

A crew of College of Toronto researchers, led by means of Professor Yu Zou within the School of Carried out Science & Engineering, is operating to advance the sphere of steel additive production on the college’s first steel 3-d printing laboratory.

The know-how, which makes use of computer-aided design (CAD) to build fabrics layer by means of layer, can beef up production throughout aerospace, biomedical, calories and car industries.

“We’re operating to discover the basic physics in the back of the additive production procedure, in addition to making improvements to its robustness and growing novel structural and useful fabrics via its packages,” says Zou, an assistant professor within the division of fabrics science and engineering.

In contrast to conventional production, by which portions or elements are constructed from bulk fabrics, the steel 3-d printing procedure permits microstructure and fabrics constitutions to be in the community adapted, which means they are able to show off distinct houses.

“As an example, clinical implants require human bone-like fabrics which are dense and tough at the outdoor, however porous at the inside of,” says Xiao Shang, a Ph.D. candidate in Zou’s lab. “With conventional production, that is in point of fact laborious to perform—however steel printing will provide you with much more regulate and custom designed merchandise.”

Subtractive production tactics in most cases comes to getting rid of subject material to be able to reach a desired finish product. Additive production, against this, builds new items by means of including layers of subject material. This procedure considerably reduces manufacturing time, subject material price and effort intake when generating items corresponding to aerospace engine elements, tooling portions for car manufacturing, vital elements for nuclear reactors and joint implants.

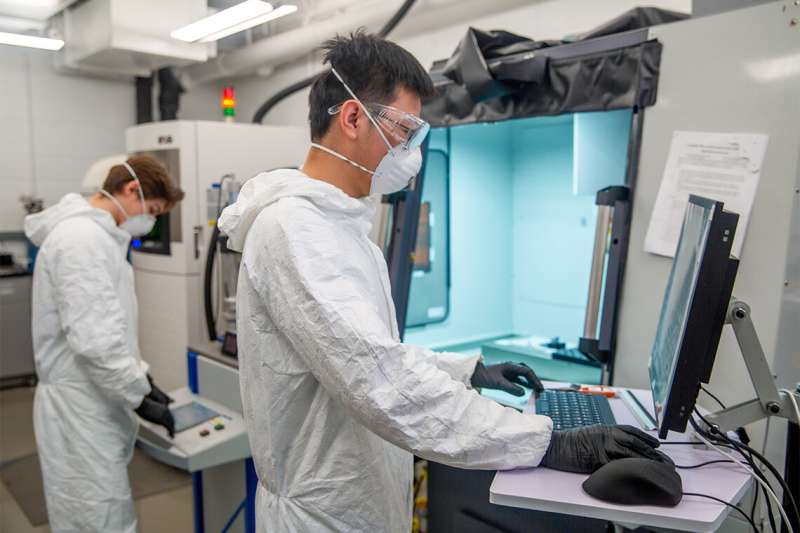

Zou’s steel 3-d printers are designed to specialise in each selective laser melting and directed calories deposition—two crucial steel additive production tactics utilized in each academia and business.

First, CAD device is used to create a 3-d fashion of the item and its layers. Then, for each and every layer, the device deposits an excessively skinny layer of steel powder, which is due to this fact melted by means of an impressive laser in step with the geometry outlined by means of the 3-d fashion.

After the molten steel solidifies, it adheres to both the former layer or the substrate. As soon as each and every layer is whole, the device will repeat the powder doping and laser melting procedure till all layers are published and the item is finished.

“Typical production tactics are nonetheless well-suited for large-scale business production,” says Tianyi Lyu, a Ph.D. candidate in fabrics science and engineering. “However additive production has features that transcend what typical tactics can do. Those come with the fabrication of complicated geometries, speedy prototyping and customization of designs, and exact regulate of the fabric houses.”

As an example, dental pros can use selective laser melting to create dentures or implants custom designed to precise sufferers by way of an exact 3-d fashion with dimensional accuracy this is inside a couple of micrometers. Speedy prototyping additionally lets in for simple changes of the denture design. And because implants can require other subject material houses at distinct places, this may also be completed by means of merely converting the method parameters.

The crew may be making use of novel experimental and analytical achieve a greater figuring out of the selective laser melting and directed calories deposition printing processes. These days, their analysis is involved in complex steels, nickel-based superalloys and high-entropy alloys, they usually might increase to discover titanium and aluminum alloys at some point.

“Some of the main bottlenecks in typical alloy design these days is the huge processing instances required to create and check new fabrics. This kind of high-throughput design simply is not conceivable for typical fabrication strategies,” says Ajay Talbot, a grasp’s scholar in fabrics science and engineering.

With additive production tactics corresponding to directed calories deposition, the crew is all of a sudden expanding the volume of alloy methods explored, changing the composition of fabrics right through the printing procedure by means of including or getting rid of positive parts.

“We also are operating against clever production. All through the steel 3-d printing procedure, the interplay between a high-energy laser and the fabric handiest lasts for a couple of microseconds. Then again, inside this restricted time-frame, multi-scale, multi-physics phenomena happen,” says Jiahui Zhang, a Ph.D. candidate in fabrics science and engineering. “Our major problem is achieving information to seize those phenomena.

“In our analysis, we now have effectively custom designed explicit device studying strategies for various portions of the steel additive production lifecycle.”

Within the lab, high-speed infrared digital camera methods are built-in at once into the steel 3-d printers. The crew has additionally constructed an in-situ tracking gadget according to the photographs taken by means of the printer to investigate and extract the important thing options of published items.

“With the advance of laptop imaginative and prescient, a well-trained deep studying fashion may just routinely accomplish some fundamental duties that human visible methods can do, corresponding to classification, detection and segmentation,” provides Zhang.

Some of the issues of present additive production processes is construction a powerful and dependable 3-d printer that may ship constant fine quality portions. To this finish, the crew is actively operating to use device studying and laptop imaginative and prescient to increase a completely self reliant closed loop-controlled 3-d printing gadget that may locate and proper defects that might differently emerge in portions made by way of additive production. Enforcing those methods may just very much widen the adoption of steel additive production methods within the business, says Zou.

Since build up the lab’s steel printing features, Zou and his crew have established partnerships with govt analysis laboratories, together with Nationwide Analysis Council Canada (NRC) and plenty of Canadian corporations, together with Oetiker Restricted, Mech Answers Ltd., EXCO Engineering and Magna World.

“Steel 3-d printing has the possible to revolutionize production as we realize it,” says Zou, who gives an additive production direction this is to be had to each undergraduate and graduate scholars. “With tough self reliant methods, the price of running those methods may also be dramatically decreased, permitting steel additive production to be followed extra extensively throughout industries international. The method additionally reduces fabrics and effort waste, main against a extra sustainable production business.”

Quotation:

Researchers advance steel 3-d printing know-how for car, calories and biomedical packages (2023, March 14)

retrieved 20 March 2023

from https://techxplore.com/information/2023-03-advance-metal-3d-technology-automotive.html

This file is matter to copyright. With the exception of any truthful dealing for the aim of personal find out about or analysis, no

section is also reproduced with out the written permission. The content material is supplied for info functions handiest.

Supply Through https://techxplore.com/information/2023-03-advance-metal-3d-technology-automotive.html