Figuring out defects in fiber composite fabrics all through the manufacturing procedure will probably be imaginable at some point due to a unique radar approach that robotically and non-destructively screens the producing means of fiber composite fabrics similar to wind turbine rotor blades. Till now, tracking has consisted of visible inspections. The Fraunhofer Institute for Prime Frequency Physics and Radar Tactics FHR collaborated with consortium companions Ruhr College Bochum, FH Aachen College of Implemented Sciences and Aeroconcept GmbH to increase an cutting edge approach within the FiberRadar mission.

All over the producing means of glass fiber strengthened structural parts, similar to the ones present in rotor blades, the fiber construction is mounted with a resin matrix. Irregularities within the alignment and/or the glide of fiber reinforcement can regulate the structural homes and because of this scale back the standard of the overall composite subject matter.

“When generating rotor blades, layers of glass fibers are layered on most sensible of one another in a shell. If this isn’t executed appropriately, it may end up in quite a lot of defects similar to undulation. However the fiber too can grow to be twisted and subsequently have an effect on the mechanical homes of the part,” explains Dr. André Froehly, mission supervisor at Fraunhofer FHR in Wachtberg.

It has up to now now not been imaginable to reliably analyze the course and layering of the fibers prior to the resin matrix is carried out, which means that defects have been handiest found out afterwards, as an example by the use of ultrasound exam. This made it inconceivable to keep watch over the method chain and led to pricey transform or once in a while even the scrapping of parts.

Nice doable for generating composites

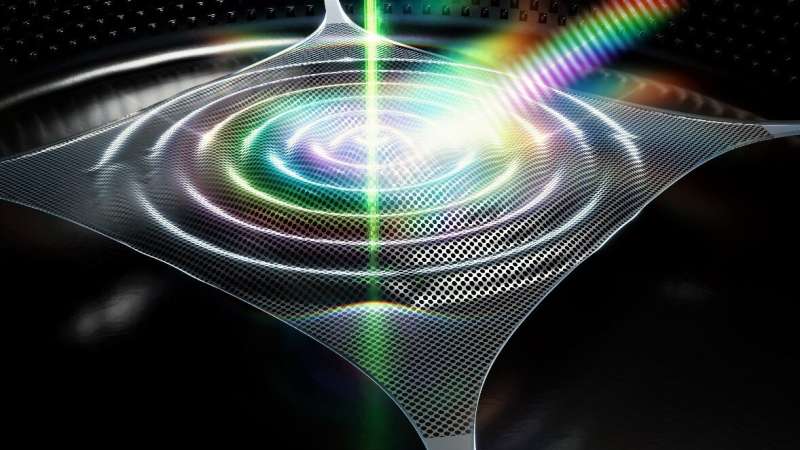

Researchers concerned within the FiberRadar mission have now advanced a brand new approach that, for the primary time, permits for checking the alignment of the decrease glass fiber layers in a non-destructive and automatic approach. The method makes use of a millimeter-wave scanning gadget consisting of a radar, a completely polarimetric robotic and related imaging device. The gadget additionally harnesses the polarization of the electromagnetic waves, so it may well additionally establish imaginable defects thru a variation within the course of polarization.

Polarization is a time period utilized in antenna generation to indicate the course of the electrical box part of an electromagnetic wave. The robotic scans the part, and at every place the radar plays a size. Those are then mixed right into a 3-d symbol by way of the device. The particular characteristic: Whilst standard radars handiest have one channel and subsequently use one polarization for each transmitting and receiving, the brand new radar sends and receives indicators in two polarizations. This now not handiest supplies high-resolution fiber construction imaging, but additionally makes it simple to reveal any defects within the deeper layers.

Moreover, refraction repayment improves the standard of the pictures: It reduces side effects because of refraction, particularly in deeper layers. By means of the usage of radar to scan the person layers, researchers too can establish any anomalies in fiber orientation and read about all the subject matter quantity in a non-destructive approach.

The FiberRadar mission mixed Ruhr College’s built-in radar generation, Fraunhofer FHR’s set of rules experience and FH Aachen’s experience in robotics to create a size gadget that permits the manufacturing of fiber composite fabrics and the keep watch over of the manufactured parts with ranges of precision that have been prior to now now not imaginable. Due to Aeroconcept GmbH’s enjoy, the generation can also be built-in at once into the producing and tracking procedure for wind turbine blade manufacturing and grow to be a key generation for top of the range composites.

“We’re very happy with the promising effects marking the top of the FiberRadar mission,” says André Froehly. “We plan to make use of follow-up initiatives to additional increase the gadget in order that it’s in a position to be used in manufacturing processes. We’re aiming to reinforce each the velocity and the intensity decision to discover much more doable defects in a shorter time frame.”

Quotation:

A singular radar method robotically screens rotor blade production processes (2023, March 1)

retrieved 8 March 2023

from https://techxplore.com/information/2023-03-radar-technique-automatically-rotor-blade.html

This file is matter to copyright. With the exception of any honest dealing for the aim of personal find out about or analysis, no

section is also reproduced with out the written permission. The content material is supplied for info functions handiest.

Supply By means of https://techxplore.com/information/2023-03-radar-technique-automatically-rotor-blade.html