Sun cells constituted of perovskite, a subject matter that is in a position to harvest daylight and convert it to electrical energy, hang nice possible instead for silicon photo voltaic cells.

In spite of awesome efficiency, potency and being inexpensive to fabricate, perovskite photo voltaic cells have now not been commercially manufactured for the shopper marketplace.

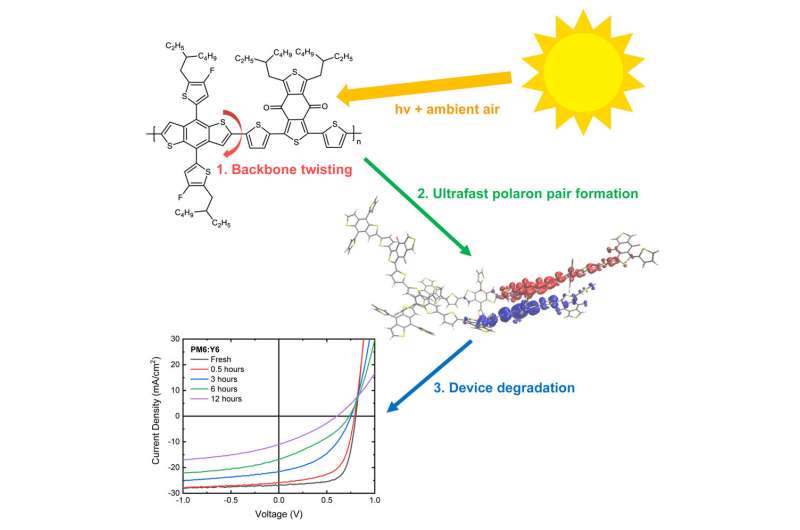

Perovskites decompose once they react with moisture and oxygen or when they’re uncovered to mild, warmth, or used for a longer time, leading to considerations that the small quantity of lead, a poisonous heavy steel, found in perovskite photo voltaic cells may pollute the surroundings when the photo voltaic mobile is broken or discarded.

The lead comes from each the perovskite subject matter and a compound used to make an element of the perovskite photo voltaic mobile, referred to as the capping layer.

Now, analysis by means of scientists from Nanyang Technological College, Singapore (NTU Singapore) and the Institute of Fabrics Analysis and Engineering (IMRE) on the Company for Science, Generation and Analysis (A*STAR) in Singapore has supplied the potential of capping fabrics in line with non-toxic metals getting used within the manufacture of perovskite photo voltaic cells.

Their find out about, printed in Nature Power in February 2023 and led by means of Professor Sum Tze Chien, Director of the Institute of Complicated Research at NTU and Affiliate Dean (Analysis) of NTU’s School of Science, and Professor Lam Yeng Ming, Chair of NTU’s College of Fabrics Science and Engineering, may take perovskite photo voltaic cells one step nearer to the marketplace.

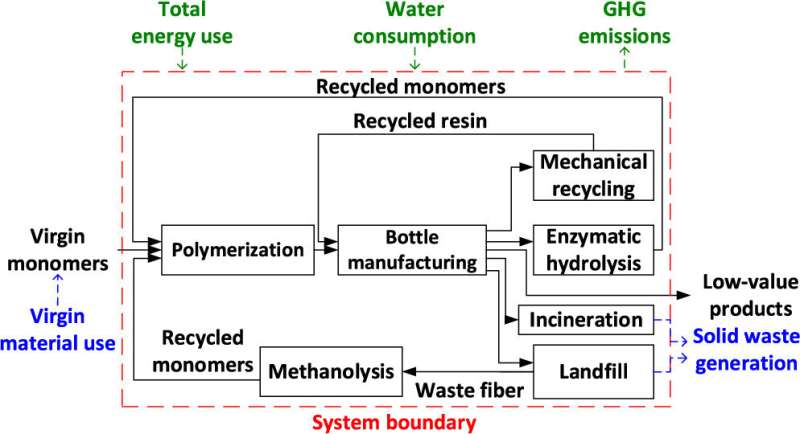

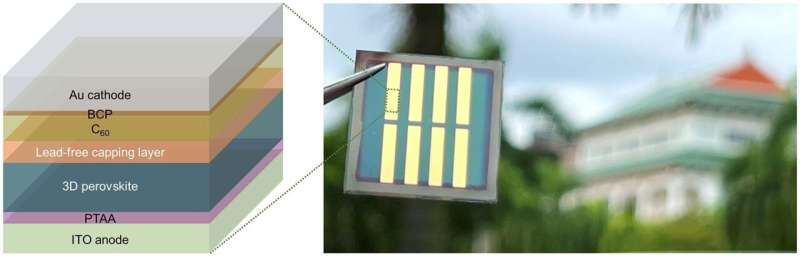

Perovskite photo voltaic cells are manufactured from a number of layers of fabrics, together with a perovskite layer that harvests mild and a capping layer. The capping layer is lined onto the perovskite layer to offer protection to the photo voltaic mobile from environmental stresses reminiscent of warmth and moisture and to spice up the efficiency of the mobile.

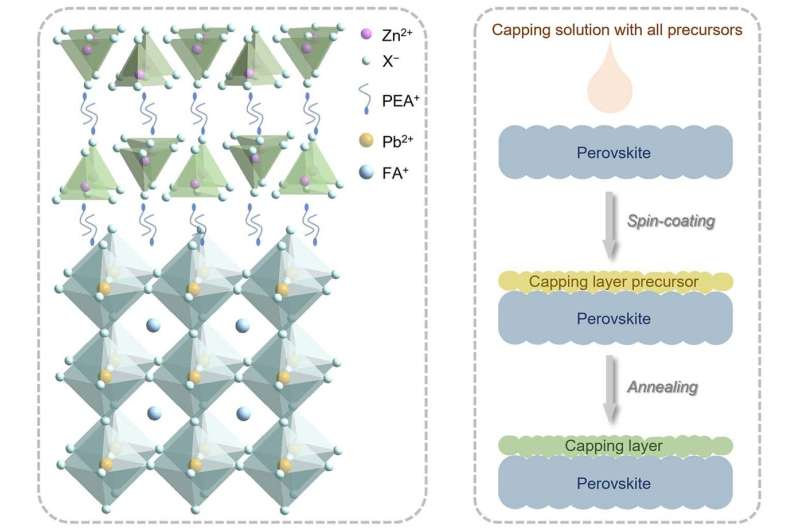

To make sure that the capping layer is suitable with the underlying perovskite layer, researchers in most cases use an manner referred to as the part precursor (HP) strategy to fabricate the capping layer. Probably the most precursor chemical compounds is first deposited on best of the perovskite layer which gives the opposite precursor. Via a procedure referred to as cation trade response, the deposited precursor then reacts with lead ions provide within the perovskite layer underneath to shape a lead-based chemical compound that makes up the capping layer.

Because of the HP means, lead may be provide within the protecting capping layer. A technique that permits non-toxic metals for use within the capping layer can be a game-changer for perovskite photo voltaic cells.

To make perovskite photo voltaic cells extra environmentally pleasant, the NTU scientists devised an manner, referred to as a complete precursor (FP) answer means, to synthesize a capping layer that doesn’t include lead.

The use of the FP means, the scientists lined perovskites with answers containing steel halide salts—compounds manufactured from a steel and components that come with chlorine, fluorine and iodine—and phenethylammonium iodide (PEAI) this is frequently carried out to perovskites to enhance the efficiency of perovskite photo voltaic cells. PEAI accommodates ammonium, a positively-charged ion that accommodates nitrogen and hydrogen, which is essential for the chemical response.

Zinc-based compound leads the best way

The researchers discovered {that a} zinc-based compound PEA2ZnX4 synthesized the usage of the process was once among the best capping subject matter a few of the different fabrics examined.

In contrast to the HP means, there is not any want to draw lead ions up from the underlying perovskite layer to shape this protecting capping layer when the FP means is used. This paves the best way for using non-toxic metals within the capping layer.

Consistent with the researchers, the FP procedure may be simpler than the HP means at fabricating the capping layer because the chemical compounds within the answer are in a position to react with every different without delay at the floor of the perovskite.

To manufacture a photo voltaic mobile capped with PEA2ZnX4, the researchers first dissolved zinc halide salts and PEAI in a solvent referred to as acetonitrile, frequently used for business programs. They then deposited the answer onto a rapidly-spinning perovskite layer connected to an electrically conductive glass substrate to shape a skinny and uniform layer—a procedure referred to as spin-coating.

The lined perovskite was once heated at 100 levels Celsius for 10 mins to bind the capping layer to the skin of the perovskite. The researchers then used a procedure referred to as vacuum evaporation, during which a subject matter is heated in a vacuum chamber to provide a vapor which is deposited at the lined perovskite, to synthesize the opposite layers of the perovskite photo voltaic mobile.

The use of the FP means, the scientists created a 1 inch by means of 1 inch prototype photo voltaic mobile capped with the zinc-based compound.

The scientists tested the zinc-based capping layer the usage of electron microscopy and spectroscopy and located that it didn’t impact {the electrical} homes of the underlying perovskite layer. The capping layer additionally helped to hide defects at the floor of the perovskite layer and advanced its light-harvesting features.

The researchers say that their means contributes to efforts to make perovskite photo voltaic cells extra environmentally pleasant. For instance, the process can be utilized along side lead-free perovskite fabrics which are these days being explored for the advance of photo voltaic cells that might now not free up poisonous metals when discarded.

The process additionally opens the potential of engineering the composition of the capping layer to support the efficiency of perovskite photo voltaic cells.

“Probably the most greatest drawbacks of the usage of perovskite photo voltaic cells is their have an effect on at the surroundings. Via enabling zinc and different non-toxic metals for use within the capping layer, our innovation probably solves a significant impediment that forestalls the well-liked use of perovskite photo voltaic cells,” stated Dr. Ye Senyun, analysis fellow from NTU’s College of Bodily and Mathematical Sciences, some of the lead researchers of the find out about.

Co-lead creator Dr. Rao Haixia, analysis fellow from NTU’s College of Fabrics Science and Engineering, stated, “As our means does now not require extracting lead ions from the perovskite, this allows the potential of the usage of quite a lot of fabrics to spice up the stableness and potency of perovskite photo voltaic cells.”

The researchers discovered that the fabricated photo voltaic mobile was once as efficient at changing daylight to power as standard perovskite photo voltaic cells. In experiments with mild that simulated daylight, the photo voltaic mobile may convert 24.1 % of the sunshine captured to electrical energy, just about the absolute best potency accomplished by means of perovskite photo voltaic cells thus far. When compared, the absolute best qualified mild conversion potency of silicon photo voltaic cells is 25.2 %.

“The capping layer is a crucial element of a perovskite photo voltaic mobile. This new method to model the capping layer is a significant milestone in designing perovskite photo voltaic cells with enhanced homes,” stated Professor Michael Grätzel, Director of the Laboratory of Photonics and Interfaces on the École Polytechnique Fédérale de Lausanne in Switzerland, who was once now not concerned within the find out about.

The prototype additionally demonstrated excellent reproducibility, with a median mild conversion charge of virtually 23 % over 103 cells examined. It had an extended lifespan, keeping up greater than 90 % of its talent to transform mild into electrical energy for greater than 1,000 hours of operation at complete capability.

The efficiency of the software was once additionally extra strong at prime temperatures in comparison to units with no capping layer.

“Via increasing the library of fabrics that can be utilized, our findings release new alternatives for creating awesome fabrics for the capping layer, for extra environment friendly and strong perovskite photo voltaic cells,” stated Prof Sum. “This lead-free protecting capping means will also be prolonged to different programs like perovskite mild emitting units, lasers and detectors.”

Prof Lam added, “As fossil fuels are depleting quickly, we want to harness renewable power assets reminiscent of solar power a lot better. Eco-friendly and strong perovskite photo voltaic cells might be the solution and this innovation can probably propel a much broader scale adoption of perovskite photo voltaic cells for solar power harvesting.”

The scientists are running on scaling up the strategy to fabricate full-sized photo voltaic cells. They’re additionally within the technique of submitting a patent with NTUitive, NTU Singapore’s innovation and endeavor corporate.

Main points of the find out about will also be present in Nature Power.

Additional info:

Yeng Lam, Increasing the low-dimensional interface engineering toolbox for environment friendly perovskite photo voltaic cells, Nature Power (2023). DOI: 10.1038/s41560-023-01204-z. www.nature.com/articles/s41560-023-01204-z

Quotation:

Stabilizing perovskite photo voltaic cells with out lead (2023, February 23)

retrieved 6 March 2023

from https://techxplore.com/information/2023-02-stabilizing-perovskite-solar-cells.html

This record is topic to copyright. Aside from any truthful dealing for the aim of personal find out about or analysis, no

section is also reproduced with out the written permission. The content material is equipped for info functions simplest.

Supply Via https://techxplore.com/information/2023-02-stabilizing-perovskite-solar-cells.html