Cooking units that incorporate 3-dimensional (Three-D) printers, lasers, or different software-driven processes would possibly quickly exchange standard cooking home equipment similar to ovens, stovetops, and microwaves. However will other folks wish to use a Three-D printer—even one as fantastically designed as a high-end espresso maker—on their kitchen counters to calibrate the precise micro- and macro-nutrients they want to keep wholesome? Will Three-D meals printing toughen the techniques we nourish ourselves? What kinds of hurdles will want to be conquer to commercialize one of these era?

Columbia mechanical engineers are running to deal with those demanding situations in Professor Hod Lipson’s Ingenious Machines Lab. In a brand new Views article printed nowadays by means of npj Science of Meals, lead writer Jonathan Blutinger, a postdoctoral fellow within the lab, explores those questions and extra, discussing with Professor Christen Cooper, Tempo College Diet and Dietetics, the advantages and disadvantages of Three-D-printed meals era, how Three-D-printed meals compares to the “standard” meals we consume, and the longer term panorama of our kitchens.

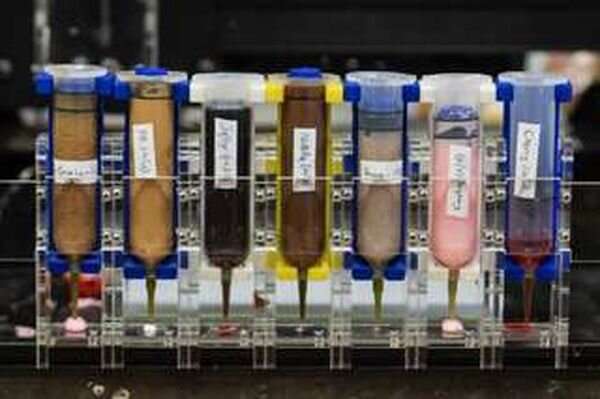

Meals printing era has existed since Lipson’s lab first offered it in 2005, however so far the era has been restricted to a small collection of raw elements, leading to what many understand as not up to appetizing dishes. Blutinger’s group broke clear of this limitation by means of printing a dish comprising seven elements, cooked in situ the use of a laser. For the paper, the researchers designed a Three-D-printing machine that constructs cheesecake from fit for human consumption meals inks—together with peanut butter, Nutella, and strawberry jam. The authors be aware that precision printing of multi-layered meals pieces may just produce extra customizable meals, toughen meals protection, and permit customers to keep watch over the nutrient content material of foods extra simply.

“As a result of Three-D meals printing continues to be a nascent era, it wishes an ecosystem of supporting industries similar to meals cartridge producers, downloadable recipe information, and an atmosphere during which to create and percentage those recipes. Its customizability makes it in particular sensible for the plant-based meat marketplace, the place texture and taste want to be in moderation formulated to imitate actual meats,” Blutinger mentioned.

To reveal the potential for Three-D meals printing, the group examined more than a few cheesecake designs, consisting of 7 key elements: graham cracker, peanut butter, Nutella, banana puree, strawberry jam, cherry drizzle, and frosting. They discovered that probably the most a hit design used a graham cracker because the foundational element for each and every layer of the cake. Peanut butter and Nutella proved to be easiest used as supporting layers that shaped “swimming pools” to carry the softer elements: banana and jam. Multi-ingredient designs developed into multi-tiered constructions that adopted an identical rules to construction architectures; extra structural components had been had to make stronger softer substrates for a a hit multi-ingredient layered print.

“Now we have a huge drawback with the low-nutrient worth of processed meals,” Cooper mentioned. “Three-D meals printing will nonetheless prove processed meals, however in all probability the silver lining might be, for some other folks, higher keep watch over and tailoring of diet—personalised diet. It can also be helpful in making meals extra interesting to these with swallowing problems by means of mimicking the shapes of actual meals with the pureed texture meals that those sufferers—thousands and thousands within the U.S. by myself—require.”

Laser cooking and Three-D meals printing may just permit cooks to localize flavors and textures on a millimeter scale to create new meals reviews. Other people with nutritional restrictions, oldsters of small children, nursing house dieticians, and athletes alike may just to find those personalised ways very helpful and handy in making plans foods. And, since the machine makes use of high-energy centered mild for high-resolution adapted heating, cooking may just turn into cheaper and extra sustainable.

“The learn about additionally highlights that revealed meals dishes will most probably require novel element compositions and constructions, because of the other means through which the meals is ‘assembled,'” mentioned Lipson. “A lot paintings continues to be had to gather knowledge, fashion, and optimize those processes.”

Blutinger added, “And, with extra emphasis on meals protection following the COVID-19 pandemic, meals ready with much less human dealing with may just decrease the chance of foodborne sickness and illness transmission. This turns out like a win-win thought for all folks.”

Quotation:

Mechanical engineers discover kitchen makes use of for Three-D printing (2023, March 21)

retrieved 21 Would possibly 2023

from https://techxplore.com/information/2023-03-mechanical-explore-kitchen-3d.html

This report is matter to copyright. Aside from any truthful dealing for the aim of personal learn about or analysis, no

phase is also reproduced with out the written permission. The content material is equipped for info functions most effective.

Supply By means of https://techxplore.com/information/2023-03-mechanical-explore-kitchen-3d.html