There is a large number of probably helpful uncooked fabrics sure up in used face mask, grocery baggage and meals wrap. Nevertheless it has been a lot less expensive to stay making extra of those single-use plastics than to recuperate and recycle them.

Now, a global analysis group led by means of the Division of Power’s Pacific Northwest Nationwide Laboratory has cracked the code that stymied earlier makes an attempt to wreck down those power plastics. They reported their discovery in lately’s factor of Science (Feb. 23).

Low temperature and response keep watch over

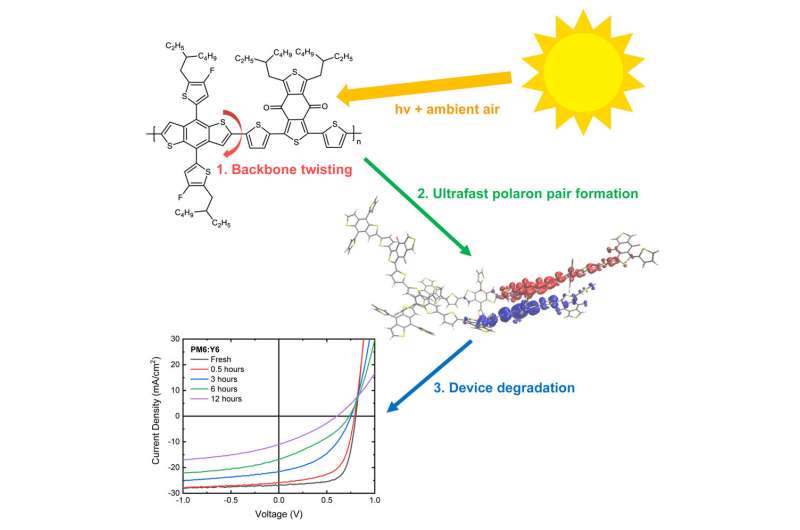

Generally, recycling plastics calls for “cracking” or splitting aside the harsh and solid bonds that still lead them to so power within the surroundings. This cracking step calls for top temperatures, making it dear and effort in depth.

The newness this is combining the cracking step with a 2nd response step that straight away completes the conversion to a liquid gasoline-like gas with out undesirable byproducts. The second one response step comes to what are referred to as alkylation catalysts. Those catalysts supply a chemical response these days deployed by means of the petroleum business to support the octane score of fuel.

Crucially, within the present learn about, the alkylation response straight away follows the cracking step in one response vessel, at close to room temperature (70 levels C/158 levels F).

“Cracking simply to wreck the bonds leads to them forming some other one in an out of control method, and that’s the reason an issue in different approaches,” mentioned Oliver Y. Gutiérrez, a learn about creator and chemist at PNNL. “The name of the game method this is that while you smash a bond in our gadget, you straight away make some other one in a focused method that will provide you with the tip product you need. That also is the name of the game that allows this conversion at low temperature.”

Of their learn about, the analysis group, co-led by means of scientists from the Technical College of Munich, Germany, pointed to split, fresh trends by means of the petroleum business to commercialize the second one a part of the method reported right here for crude oil processing.

“The truth that business has effectively deployed those rising alkylation catalysts demonstrates their solid, tough nature,” mentioned Johannes Lercher, a senior creator of the learn about, director of PNNL’s Institute for Built-in Catalysis, and professor of chemistry at TUM. “This learn about issues to a sensible new strategy to shut the carbon cycle for waste plastic this is nearer to implementation than many others being proposed.”

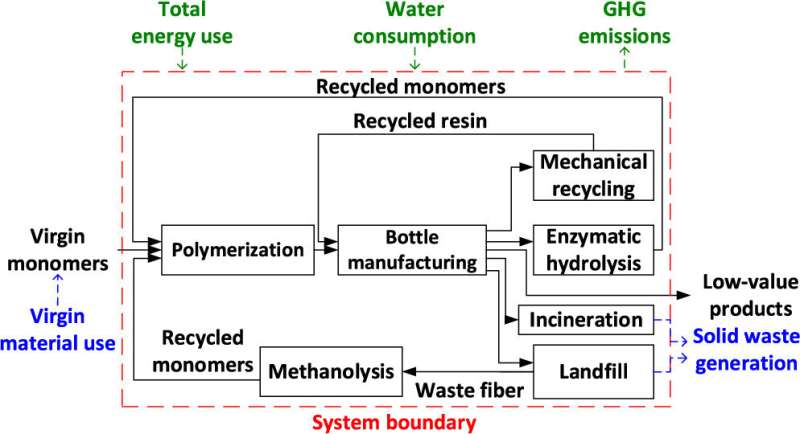

Of their learn about, the researchers notice a limitation on their findings. The method works for low-density polyethylene merchandise (LDPE, plastic resin code #4), equivalent to plastic motion pictures and squeezable bottles, and polypropylene merchandise (PP, plastic resin code #5) that don’t seem to be most often accumulated in curb-side recycling methods in the USA. Top-density polyethylene (HPDE, plastic resin code #2) will require a pretreatment to permit the catalyst get right of entry to to the bonds it wishes to wreck.

Seeing waste plastic as long term gas and new merchandise

Petroleum-based plastic waste is an untapped useful resource that may function the beginning subject matter for helpful sturdy fabrics and for fuels. Greater than part of the 360 million lots of plastics produced globally every 12 months are the plastics focused on this learn about. However taking a look at a mountain of plastic and seeing its worth calls for an innovator’s mindset, a chemist’s ingenuity, and a realist’s working out of the economics concerned. Those scientists are looking to exchange the dynamic by means of making use of their experience in successfully breaking chemical bonds.

“To unravel the issue of power waste plastic, we wish to succeed in a vital level the place it makes extra sense to assemble it and go back it to make use of than to regard it as disposable,” mentioned Lercher. “We now have proven right here that we will make that conversion temporarily, at delicate stipulations, which supplies one of the most incentives to transport ahead to that tipping level.”

Additional information:

Wei Zhang et al, Low-temperature upcycling of polyolefins into liquid alkanes by the use of tandem cracking-alkylation, Science (2023). DOI: 10.1126/science.ade7485. www.science.org/doi/10.1126/science.ade7485

Quotation:

Plastic upcycling to near the carbon cycle (2023, February 23)

retrieved 4 March 2023

from https://techxplore.com/information/2023-02-plastic-upcycling-carbon.html

This record is topic to copyright. With the exception of any honest dealing for the aim of personal learn about or analysis, no

phase is also reproduced with out the written permission. The content material is supplied for info functions handiest.

Supply By way of https://techxplore.com/information/2023-02-plastic-upcycling-carbon.html