Norway is Europe’s greatest manufacturer of aluminum and silicon. The steel business is likely one of the nation’s maximum vital export industries, but in addition accounts for 10% of its CO2 emissions.

Norway urgently wishes to chop its emission ranges within the present manufacturing strategies to be able to achieve its local weather goals.

Out with carbon

NTNU has taken out a patent for an commercial procedure that can take away all direct emissions of CO2 and NOx. The method has been named SisAl.

Quartz is the uncooked subject matter in each the normal smelting procedure and the usage of the SisAl approach. With lately’s era, CO2 is shaped when quartz reacts with carbon. As an alternative of carbon, the SisAl procedure makes use of aluminum as a lowering agent, thus warding off the formation of CO2.

“Technologically, we imagine that not anything stands in the best way of manufacturing silicon on an commercial scale with the brand new approach. And it is energy-saving,” says Maria Wallin, a fabrics researcher at NTNU.

The SisAl procedure is exothermic, which means the response between quartz and aluminum releases calories. Lately’s approach is endothermic, and effort must be added to scale back the quartz. SisAl makes use of just one 3rd the calories intake consistent with ton of completed silicon.

The standard era makes use of 85% to 92% of the quartz this is put within the furnace. SisAl makes use of 97% to 99% since the procedure too can use quartz in powder shape.

Wallin and Professor Gabriella Tranell co-coordinate the huge EU initiatives SisAl Pilot and SisAl Slag, which might be led via NTNU. Twenty-two companions in analysis and business in Europe and South Africa have advanced the method in line with NTNU’s patent.

Dozens of pilot exams were performed at Elkem’s pilot heart at Fiskaa in Kristiansand and on the Fundiciones Rey foundry in Spain.

Egg of Columbus

Wallin says the SisAl approach has plenty of different benefits.

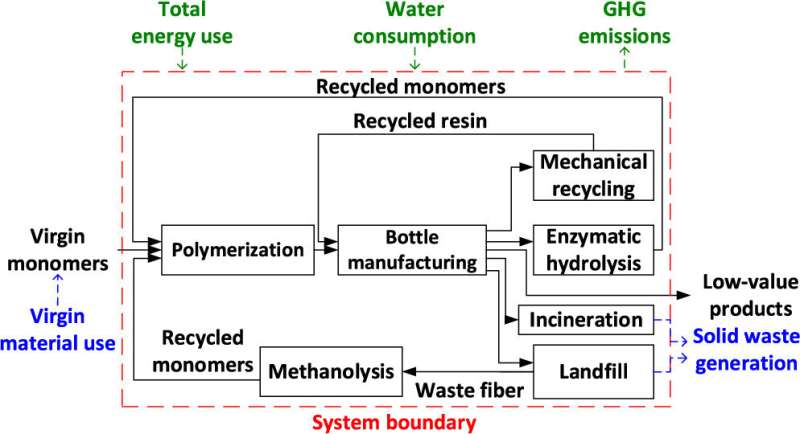

Along with getting rid of all direct emissions of CO2 and NOx and saving calories, the brand new silicon-making procedure will use slag (dross) and scrap from the aluminum business.

The SisAl procedure can use slag as a lowering agent in silicon manufacturing. The similar applies to skinny aluminum scrap, for instance from meals packaging.

The SisAl procedure additionally creates slag, equivalent to calcium oxide and aluminum oxide, however those are components which might be in call for via the metal business, says Wallin.

The brand new smelting procedure additionally makes higher use of the uncooked subject matter, as a result of positive quartz (“fines”) can be utilized. Within the conventional procedure, fines need to be got rid of.

Round economic system

“The problem we are spending probably the most time on presently is making a round industry style that comes with the steel industries. We see nice alternatives for synergies that would receive advantages each the surroundings and the economic system,” Wallin stated.

“We are taking a look to raised make the most of uncooked fabrics, and to seek out the bottom imaginable emissions, much less calories intake, most reuse and the least imaginable waste. The dimensions of tax the government position on CO2 emissions is after all additionally an element within the calculation,” says Wallin.

Subsequent steps

Silicon is produced via Elkem and Wacker in Norway. Wallin believes that lately’s smelters for silicon may use the SisAl era with out huge investments as a complement, or partial substitute, for present manufacturing.

A pilot plant for SisAl manufacturing is being inbuilt South Africa as a part of an EU venture. Wallin considers this a milestone prior to the eventual development of a facility on an commercial scale.

EU aiming to be self-sufficient

The EU has designated silicon as a seriously vital steel. Silicon has semiconductor homes and is a essential subject matter in circuit forums, sun cells and all electronics.

Silicon, in alloys with aluminum, could also be part of lots of the on a regular basis fabrics we use. Lately, China accounts for two-thirds of silicon manufacturing on the planet.

International manufacturing of aluminum is 60 million metric heaps. Silicon manufacturing is 12 million metric heaps. Europe produces not up to part of its wishes. The EU is raring to develop into extra self-sufficient in key metals, which has develop into a big precedence because the invasion of Ukraine. The Ecu Fee additionally believes that the silicon, aluminum and ferroalloy industries possibility being moved to cheap nations given the stricter environmental necessities in Europe.

Aluminum scrap is exported yearly from Europe to the track of 600,000 metric heaps. The EU objectives to section out those exports to keep away from shedding treasured uncooked fabrics.

Norway in a dream place

Because of hydropower, Norwegian steel manufacturing is without doubt one of the cleanest on the planet. Iceland is in the similar magnificence on account of its geothermal calories and hydropower.

“Norway is in a novel place as a way to produce silicon and aluminum via much more environmentally pleasant strategies than is finished lately. For silicon, I believe we are just about a technological shift. So much could also be going down within the aluminum business. On the identical time, the potential of cleaner manufacturing and higher useful resource usage is even larger when two vital industries can paintings in combination,” Wallin stated.

“Norway additionally has the good thing about brief delivery distances between the amenities of the 2 industries. We imagine the SisAl procedure can utterly exchange the present approach, however it is going to most definitely take time,” she stated.

A model of the analysis has been revealed at the pre-print server SSRN Digital Magazine.

Additional information:

Harald Philipson et al, Initial Techno-Financial Concerns of the Sisal Procedure—Remaining Fabrics Loops via Commercial Symbiosis, SSRN Digital Magazine (2022). DOI: 10.2139/ssrn.4116381

Quotation:

Inexperienced manufacturing of silicon could also be simply across the nook (2023, February 23)

retrieved 9 March 2023

from https://techxplore.com/information/2023-02-green-production-silicon-corner.html

This file is topic to copyright. With the exception of any honest dealing for the aim of personal find out about or analysis, no

section could also be reproduced with out the written permission. The content material is equipped for info functions simplest.

Supply By way of https://techxplore.com/information/2023-02-green-production-silicon-corner.html