With the new explosive call for for records garage, starting from records facilities to quite a lot of good and attached gadgets, the will for higher-capacity and extra compact reminiscence gadgets is continuously expanding. Consequently, semiconductor gadgets at the moment are transferring from 2-D to three-D. The three-D-NAND flash reminiscence is probably the most commercially a success three-D semiconductor instrument as of late, and its call for for supporting our data-driven global is now rising exponentially.

The scaling legislation for three-D gadgets is completed via stacking an increasing number of semiconductor layers, smartly above 100 layers, in a extra dependable manner. As each and every layer thickness corresponds to the efficient channel duration, correct characterization and keep watch over of layer-by-layer thickness is important. Up to now, sadly, non-destructive, correct dimension of each and every layer thickness of such hundreds-layers construction has no longer been imaginable, which units a major bottleneck one day scaling of three-D gadgets.

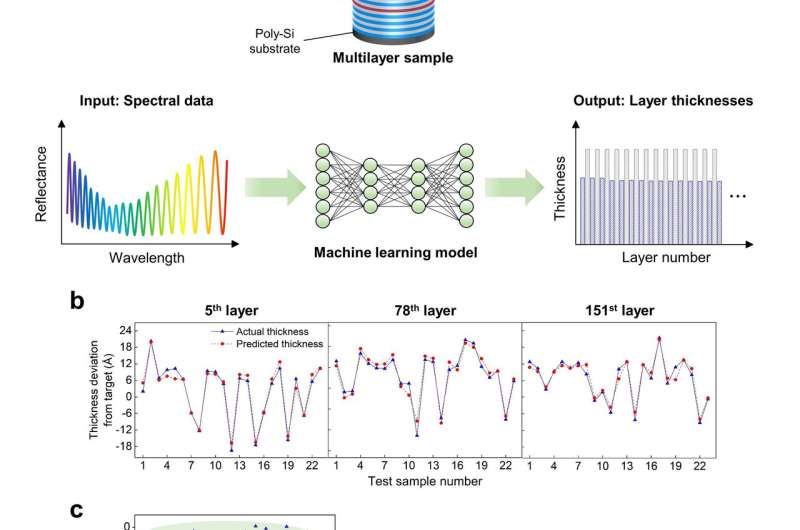

In a brand new paper printed in Mild: Complex Production, a crew of engineers from Korea Complex Institute of Science and Generation (KAIST) and Samsung Electronics Co. Ltd., led via Professor Jungwon Kim of KAIST, South Korea, has evolved a non-destructive thickness characterization way via combining optical spectral measurements and device studying. Via exploiting the structural similarity between semiconductor multilayer stacks and dielectric multilayer mirrors, spectroscopic optical measurements, together with ellipsometric and reflectance measurements, are hired. System studying is then used to extract the correlation between spectroscopic dimension records and multilayer thickness. For greater than 200 layers of oxide and nitride multilayer stack, the thickness of each and every layer over all of the stack may well be made up our minds with a mean of roughly 1.6 Å root-mean-square error.

Along with the correct resolution of the multilayer thickness beneath commonplace fabrication prerequisites, which is beneficial for controlling etching and deposition processes, the analysis crew evolved any other device studying style that may stumble on outliers when layer thicknesses considerably range from the design goal. It used a lot of simulated spectral records for more practical and economical coaching, and may just effectively stumble on the misguided gadgets and the precise misguided layer location within the instrument.

“The device studying method comes in handy for getting rid of measurement-related problems,” stated Hyunsoo Kwak, a doctoral scholar at KAIST and primary creator of the find out about. “Via the use of noise-injected spectral records as enter to the device studying set of rules, we will get rid of quite a lot of mistakes from dimension tools and adjustments in subject material houses beneath other fabrication prerequisites,” he added.

“This system can also be readily implemented for the overall inspection of quite a lot of three-D semiconductor gadgets,” stated Professor Kim, “which is exemplified via the truth that all of the records used on this paintings have been acquired in industrial three-D NAND production strains of Samsung Electronics.”

Additional information:

Hyunsoo Kwak et al, Non-destructive thickness characterisation of 3-D multilayer semiconductor gadgets the use of optical spectral measurements and device studying, Mild: Complex Production (2021). DOI: 10.37188/lam.2021.001

Quotation:

Angstrom multilayer metrology via combining spectral measurements and device studying (2021, January 21)

retrieved 6 April 2023

from https://phys.org/information/2021-01-angstrom-multilayer-metrology-combining-spectral.html

This record is matter to copyright. Aside from any honest dealing for the aim of personal find out about or analysis, no

section is also reproduced with out the written permission. The content material is equipped for info functions simplest.

Supply Via https://phys.org/information/2021-01-angstrom-multilayer-metrology-combining-spectral.html