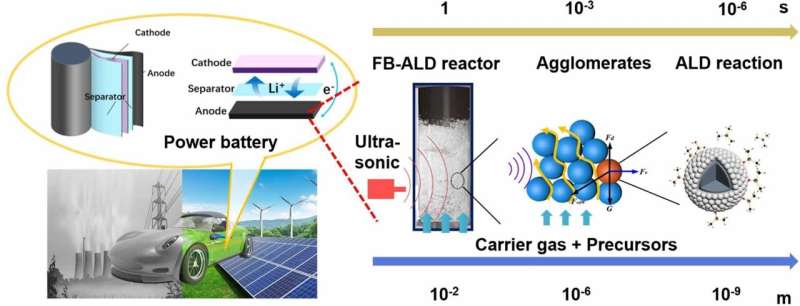

Floor amendment of micro-nanoparticles on the atomic and close-to-atomic scales is of serious significance to their packages in quite a lot of fields, comparable to power garage, catalysis, sensors, and biomedicine. In an effort to meet the business necessities in those spaces, it’s urgently vital to increase high-volume production of atomically exact coatings on particulate fabrics. As a complicated excessive production way, atomic layer deposition (ALD) is a skinny movie deposition way which gives pinhole-free motion pictures with exact thickness regulate on the angstrom stage and remarkable homogeneity on advanced constructions. Fluidized mattress ALD (FB-ALD) has proven nice possible in atomically ultrathin motion pictures on massive quantities of debris.

In a brand new paper revealed within the Global Magazine of Excessive Production, a workforce of researchers, led through Prof. Rong Chen from the State Key Laboratory of Virtual Production Apparatus and Generation, Faculty of Mechanical Science and Engineering, Huazhong College of Science and Generation, China, have comprehensively examine the impact of ultrasonic vibration at the hydrodynamics and the particle agglomeration conduct in an FB-ALD reactor by the use of CFD-DEM simulation. The mattress drive drops and expansions, fluid turbulent kinetic power, distribution of particle velocities and forged quantity fraction in addition to the agglomerate sizes are introduced to signify the fluidization high quality. Other amplitudes and frequencies of ultrasonic vibrations are investigated to search out the optimum stipulations for boosting the fluidization high quality and the coating potency of FB-ALD procedure.

In an effort to examine the impact of ultrasonic vibration at the normal fluidization behaviors, a standard ultrasonic vibration with a frequency of 20 kHz and an amplitude of 20 µm is carried out to the FB after the fluidization reaches a gradual state. With the induce of the ultrasonic vibration, the speed of the debris on the subject of the vibrating wall will increase straight away. The choice of debris with excessive velocities additionally will increase, resulting in extra particle–particle collisions. But even so, the mattress top will increase steadily as time will increase, which signifies that the ultrasonic vibration can successfully advertise particle dispersion. Additionally, channeling may be lowered through the ultrasonic box. Those enhancements of fluidization behaviors are recommended to the particle coating procedure, for the reason that precursor molecules can diffuse quicker and extra uniformly into the agglomerates, thus expanding the full coating potency.

Fluid turbulent movement is the principle reason why for debris to reach random movement, and turbulence kinetic power is the important thing issue for comparing the breakage power for particle agglomerates. With out the ultrasonic vibration, the turbulence kinetic power is fairly small, and it stays unchanged. Alternatively, as soon as the ultrasonic vibration is carried out, the utmost turbulence kinetic power will increase sharply. It’s proven that the utmost turbulence kinetic power will increase with the frequency or amplitude expanding.

Characterizations of the coordination quantity and agglomerate measurement distribution for all instances also are performed to quantitatively examine the particle agglomeration and breakage behaviors. When the ultrasonic frequency is ready as 20 kHz, the de-agglomeration impact of the ultrasonic box will increase with the ultrasonic amplitude. When the ultrasonic frequency will increase from 10 kHz to twenty kHz, the likelihood for the agglomerates shaped through two number one debris will increase impulsively, whilst the agglomerates shaped through 3 to 10 number one debris all lower. This means that the ultrasonic vibration with the frequency of 20 kHz can additional ruin the small agglomerates into the smallest agglomerate and even person debris.

To ensure the simulation effects, comparative coating experiments were carried out with ultrasonic vibration-assisted FB-ALD reactor on NCM811 debris, which is able to be offering excessive power density in automobile lithium-ion batteries (LIBs). The SEM pictures of the covered nanoparticles additionally display that, the debris within the ultrasonic vibration-assisted FB-ALD were successfully dispersed, resulting in extra conformal layers and a better coating potency. The experimental information agree smartly with the simulation effects, which has verified the effectiveness of the dynamic multiscale CFD-DEM type.

Professor Chen Rong and different researchers in her crew replied questions on a number of key issues when appearing the ultrasonic vibration-assisted FB-ALD generation:

Is the present CFD-DEM type of FB with a measurement of a couple of millimeters exact sufficient to are expecting the particle behaviors in a scale-up ultrasonic-vibration assisted FB-ALD reactor?

“Even if the present multiscale CFD-DEM type covers scales best from the straightforward agglomerates to the FB with a measurement of a couple of millimeters, it has effectively printed the particle agglomeration and breakage behaviors with ultrasonic help. With the improvement of the multiscale idea and computational science, this type is thought to be additional evolved for a greater investigation from lab-scale to manufacturing-scale.”

How does the ultrasonic vibration affect the agglomerate breakage? Is it at all times higher to make use of upper ultrasonic frequencies?

“There exists a essential price of the ultrasonic frequency. When the ultrasonic price is less than the essential price, the typical particle pace and the agglomerate measurement building up with the ultrasonic frequency expanding. Alternatively, when the ultrasonic frequency exceeds this essential price (e.g. 40 kHz) the debris start to agglomerate close to the vibrating wall.”

What facets will have to we believe when optimizing the method parameters or designing the ultrasonic-vibration FB-ALD reactor for the coating of enormous quantities nanoparticles?

“The choices of the ultrasonic frequencies or amplitudes will depend on many elements, such because the reactor drive, the identical inter-particle cohesive forces, in addition to the particle measurement distribution in the entire FB. For the optimum design reactor, wisdom from adjoining fields comparable to hydromechanics and mechanical engineering is additional required.”

Researchers have advised that quite a lot of forms of particulate fabrics are going to profit so much from the ultrasonic vibration-assisted FB-ALD generation. The help of ultrasonic vibration can successfully boost up the speed of fluid and debris close to the vibrating wall. Enhanced fluidization high quality of nanoparticles may be certain to facilitate the warmth switch and precursor diffusion in the entire FB-ALD reactor and the agglomerates, which is able to in large part enhance the coating potency.

Additional information:

Zoushuang Li et al, A mixed multiscale modeling and experimental find out about on floor amendment of high-volume micro-nanoparticles with atomic accuracy, Global Magazine of Excessive Production (2022). DOI: 10.1088/2631-7990/ac529c

Supplied through

Global Magazine of Excessive Production

Quotation:

Floor amendment of high-volume micro-nanoparticles with atomic accuracy (2022, July 13)

retrieved 21 February 2023

from https://phys.org/information/2022-07-surface-modification-high-volume-micro-nanoparticles-atomic.html

This report is matter to copyright. Except for any honest dealing for the aim of personal find out about or analysis, no

phase is also reproduced with out the written permission. The content material is equipped for info functions best.

Supply By way of https://phys.org/information/2022-07-surface-modification-high-volume-micro-nanoparticles-atomic.html